Description

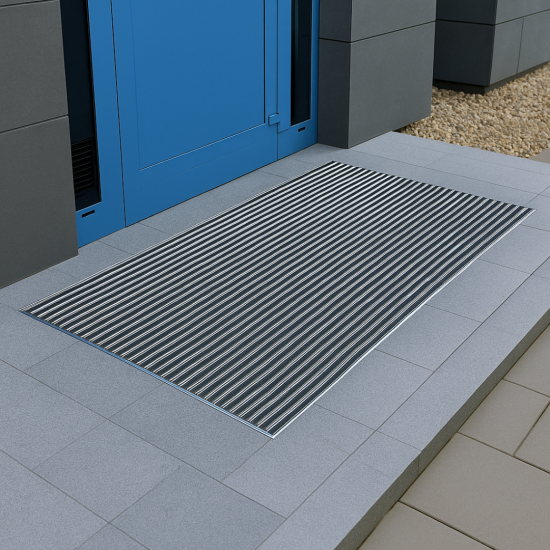

When your facility demands maximum durability combined with superior moisture management, the 1-5/8″ aluminum foot grille delivers decades of reliable performance. Unlike surface-mounted entrance mats that can shift or create trip hazards, this recessed system becomes a permanent part of your building’s entrance architecture.

Universal Floor Mats specializes in custom aluminum entrance systems for commercial properties, government facilities, and high-traffic institutional buildings. With over two decades of experience serving facility managers across the MD/DC/VA region and nationwide, we understand the critical role entrance systems play in building maintenance and safety.

Engineering & Construction

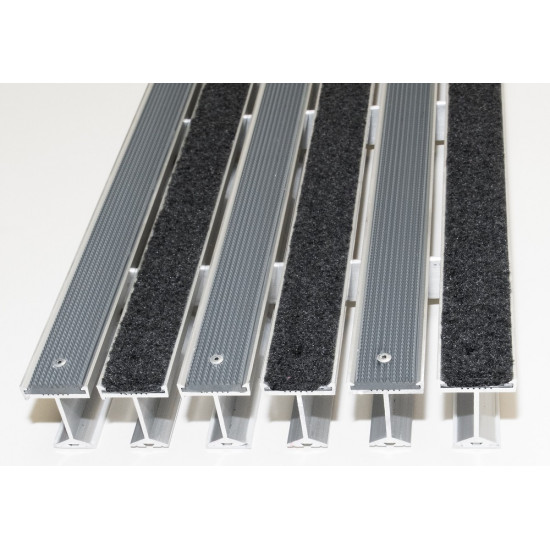

Premium Aluminum Construction Every foot grille is fabricated from 6063-T52 aluminum extrusions, the same alloy specified for architectural applications requiring superior strength and corrosion resistance. Rails are spaced at 1-1/2″ on center, providing optimal scraping performance while supporting rolling loads up to 300 pounds per wheel.

Patented Keylock Assembly Rail security is critical in high-traffic applications. Our keylock bars are placed on 6″ centers and both mechanically locked and welded in place for maximum strength. This dual-locking system prevents rail displacement even under heavy cart traffic and aggressive snow removal equipment.

Vibration-Reducing Footers Thermoplastic footers on the underside of each grille reduce metal-to-concrete contact noise when carts and equipment roll across the surface. These footers also protect the pit floor and allow for minor elevation adjustments during installation.

Performance Benefits

Moisture Management The open-grid design allows dirt, snow, and water to fall through to the recessed pit below rather than being tracked into your facility. In high-precipitation regions, optional drain pans can be integrated to handle significant volumes of runoff.

Long-Term Durability While tread inserts may require periodic replacement based on traffic volume, the aluminum grille structure itself provides decades of service. The non-corrosive properties of 6063-T52 aluminum ensure consistent performance even in coastal or de-icing chemical environments.

Maintenance Efficiency Unlike roll-up recessed mats, aluminum foot grilles remain in place and can be maintained by periodic vacuuming of the pit below. For deep cleaning, grilles can be lifted out using standard material handling equipment, cleaned, and reinstalled.

Customization Options

Aluminum Finishes

- Mill Finish: Natural aluminum appearance, most economical

- Clear Anodized: Enhanced corrosion resistance with bright appearance

- Medium Bronze Anodized: Warm architectural tone

- Dark Bronze Anodized: Contemporary dark finish

- Black Anodized: Modern aesthetic for premium installations

Tread Insert Options

Polybrush Inserts Polypropylene brush inserts provide aggressive scraping action for maximum soil removal. Available in multiple colors to coordinate with your building’s design. Ideal for locations with heavy foot traffic and significant soil loading.

Serrated Aluminum Treads Low-profile serrated aluminum provides a durable, all-metal solution with excellent water drainage. Recommended for areas with high cart traffic or where brush insert replacement would be logistically challenging.

Carpet Inserts Combination systems alternating carpet inserts with other tread types provide both scraping and moisture absorption. The carpet captures finer particles and provides a more comfortable walking surface. Available in multiple colors.

Vinyl Inserts Vinyl tread inserts offer the most economical option while still providing effective scraping performance. Available in various colors, vinyl inserts are easily replaceable and suitable for moderate traffic applications.

Frame Systems Explained

Selecting the proper frame is critical to installation success and long-term performance. Universal Floor Mats offers three primary frame configurations:

Frame 420 L&P – Level Bed (Wet Pour) Designed for new construction where the frame is set directly into wet concrete. Lag bolts secure the frame before the concrete cures, ensuring perfect alignment. The 1/2″ aluminum reveal creates a clean transition from floor to grille. This system requires coordination with concrete placement and must account for finish floor thickness.

Best for: New construction, major renovations where concrete work is scheduled

Frame 421 L&P – Deep Recess (With or Without Drain Pan) Our most robust frame system, designed for recess depths exceeding 4 inches. Vertical cross supports and reinforced lag bolt mounting make this the preferred choice for high-precipitation areas or facilities expecting significant snow and water infiltration. Available with integrated drain pans for directing moisture to building drainage systems.

Best for: Extreme weather climates, facilities with high water management requirements, government specifications requiring maximum capacity

Frame 420/422 Combination (With or Without Pan) This hybrid system provides a 2-23/32″ recess depth with cross supports under the grille for intermediate moisture retention needs. Surface reveal is 1/2″ with lag bolt mounting. Suitable for retrofit applications where moderate pit depth is available.

Best for: Retrofit projects with existing shallow recesses, commercial buildings with moderate weather exposure

Installation Considerations

Traffic Direction Proper orientation of the grille relative to primary foot traffic flow optimizes scraping performance. Rails should run perpendicular to the direction of travel, ensuring maximum contact between footwear and tread surfaces.

Pit Requirements Recessed systems require proper pit design to function effectively:

- Minimum depth must accommodate grille thickness plus frame height

- Account for finish floor material thickness when setting frames

- Ensure adequate drainage if using systems without drain pans

- Provide access for pit cleaning and maintenance

Coordination with Trades Successful installation requires coordination between concrete contractors, finish flooring installers, and the entrance system installation team. Universal Floor Mats can ship frames ahead of grilles when construction schedules require early setting.

Specifications for Architects & Facility Managers

Material Standards

- Aluminum: 6063-T52 alloy per ASTM B221

- Keylock bars: Welded and mechanically locked on 6″ centers

- Rail spacing: 1-1/2″ on center

- Weight capacity: 300 lbs per wheel

Dimensional Information

- Grille depth: 1-5/8″

- Frame reveal: 1/2″ (standard)

- Custom sizing: Any length or width to match architectural openings

- Modular construction available for large installations

Maintenance Requirements

- Periodic pit cleaning (frequency depends on traffic and weather)

- Tread insert replacement based on wear (varies by material and traffic)

- Annual inspection of keylock integrity recommended

- No special cleaning chemicals required

Why Universal Floor Mats?

Universal Floor Mats brings over 20 years of commercial flooring expertise to every aluminum foot grille installation. We understand the challenges facility managers face:

- Custom fabrication ensures perfect fit for your architectural opening

- Professional installation services available throughout MD/DC/VA region and nationwide for larger projects

- Direct manufacturer pricing eliminates distributor markups

- Technical support from experienced flooring professionals who’ve specified systems for government facilities, hospitals, corporate campuses, and educational institutions

- Fast turnaround on quotes and detailed specifications for architectural submittals

Applications

Commercial Facilities Corporate office buildings, retail centers, hotels, and hospitality venues benefit from the professional appearance and long-term durability of aluminum foot grille systems.

Government Installations Federal, state, and municipal buildings require entrance systems that meet stringent specifications for accessibility, durability, and life-cycle cost. Our systems comply with government procurement standards and can include required documentation.

Educational Institutions Schools and universities need entrance systems that withstand intense daily traffic while minimizing maintenance demands. The permanent nature of recessed systems eliminates the trip hazards associated with surface mats.

Healthcare Facilities Hospitals and medical centers require entrance systems that control soil and moisture while maintaining safe, accessible passageways. Aluminum systems provide the durability and cleanability healthcare environments demand.

Industrial & Manufacturing Facilities with cart traffic, forklift access, and heavy soil loading need entrance systems engineered for extreme conditions. The 300 lb per wheel capacity handles industrial equipment safely.

Reviews

There are no reviews yet.