RECOMMENDED MAINTENANCE SCHEDULE

High-Traffic Facilities (250+ entries per day):

• Daily surface cleaning

• Weekly frame and well cleaning

• Bi-weekly system inspection

Moderate-Traffic Facilities (50-250 entries per day):

• Surface cleaning 2-3 times per week

• Monthly frame and well cleaning

• Monthly system inspection

Seasonal Considerations:

During winter months (November through March), increase cleaning frequency by 50% due to increased tracking of salt, sand, moisture, and debris.

DAILY SURFACE MAINTENANCE

Carpet Insert Cleaning:

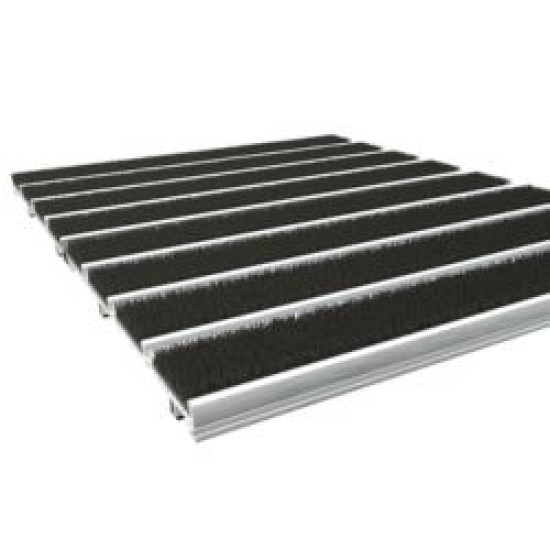

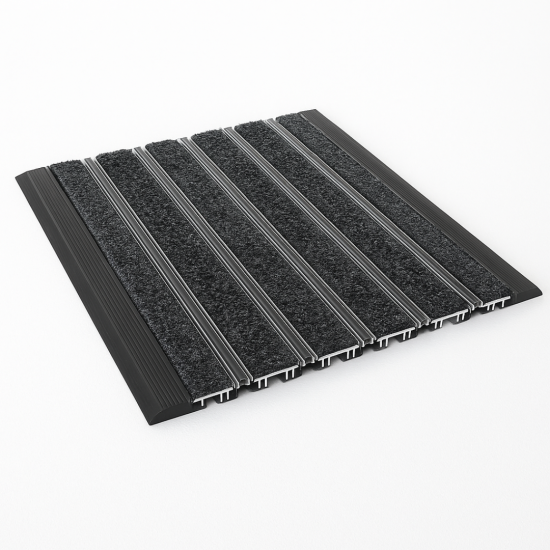

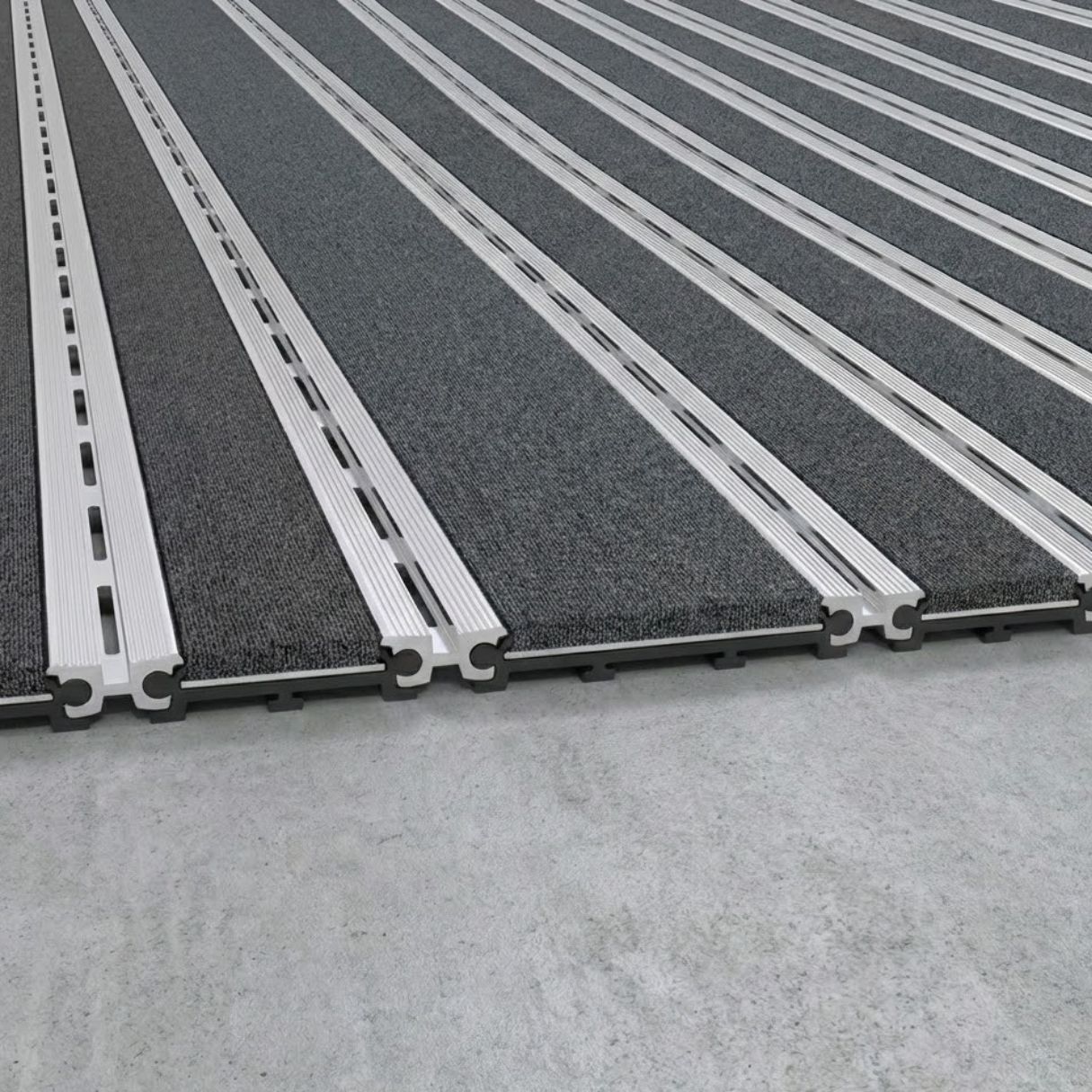

Vacuum thoroughly using a commercial-grade vacuum cleaner. For optimal results, ensure the vacuum head moves lengthwise along the grill components to maximize soil extraction from both the carpet fibers and aluminum channels. The vacuum head should have adequate depth to reach into all surface variations.

Vinyl Insert Cleaning:

Begin with vacuuming to remove loose debris. Follow with damp mopping using a mild soap and water solution. Allow the surface to air dry completely before heavy foot traffic resumes.

Stiff Brush Cleaning:

For dry debris accumulation, use a stiff-bristled brush to dislodge particles before vacuuming. This is particularly effective for sand, salt crystals, and dried mud.

SPOT CLEANING PROCEDURES

General Spill Protocol:

Address spills promptly to prevent staining and reduce slip hazards. Work from the outer edge of the spill toward the center to avoid spreading the contamination.

Dry Spills:

Brush debris into a dustpan or vacuum immediately.

Liquid Spills (Small):

Blot with absorbent material (clean cloth or paper towels). Follow with a damp cloth using mild soap and water. Blot dry with a clean cloth.

Liquid Spills (Large):

Use a wet/dry vacuum for rapid extraction. For stubborn residue, a hot water extraction machine may be employed on carpet inserts.

Chewing Gum Removal:

Remove gum promptly before it hardens. Apply a commercial gum removal gel according to manufacturer directions. Use a plastic spatula to lift the gum gently—avoid metal tools that may scratch aluminum surfaces. The cleaned area may appear slightly lighter than surrounding material; this is normal.

FRAME AND WELL CLEANING

Frequency:

Weekly during winter months; monthly during other seasons. Adjust based on your facility’s specific traffic patterns and environmental conditions.

Preparation:

Before lifting the mat modules, thoroughly vacuum the surface to remove loose debris. This prevents material from falling into the well during removal.

Module Removal:

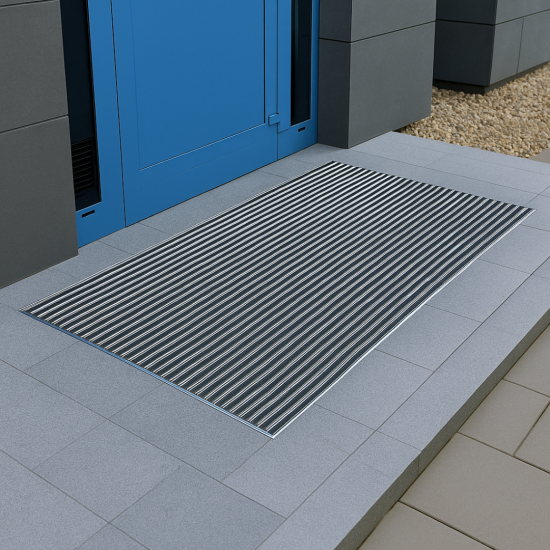

Carefully lift individual mat sections from the recessed frame. If your system features hinged connections, handle with care to avoid stressing or damaging the hinge mechanisms. Roll the mat sections loosely for temporary storage during cleaning.

Well and Frame Cleaning:

Vacuum the recessed well thoroughly to remove all accumulated dirt, debris, and moisture. Wipe down the aluminum frame with a solution of mild soap and warm water using a mop, sponge, or cloth. For stubborn residue, a soft-bristled brush may be used.

CRITICAL:

Ensure the recessed well is completely dry before reinstalling mat modules. Any remaining moisture or debris can cause the mats to warp, create uneven surfaces, and lead to long-term structural problems. If water drainage systems are present, verify they are functioning properly and free from blockages.

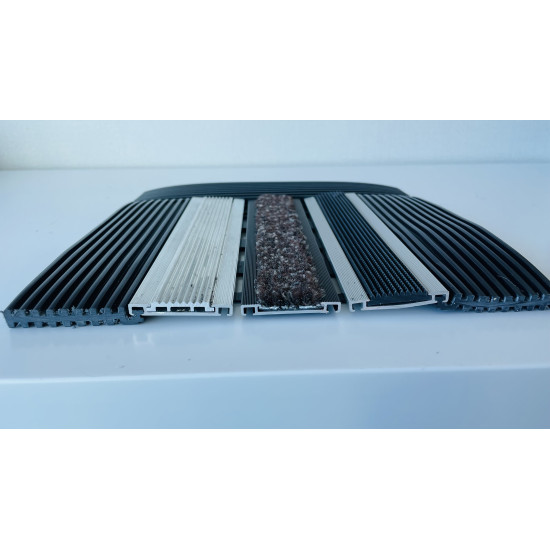

ALUMINUM SURFACE CARE

Standard Cleaning:

Clean aluminum rails and components with warm water and a pH-neutral soap. Rinse thoroughly with clean water and allow to air dry completely.

Stainless Steel Options:

For facilities that have selected stainless steel components, a specialized stainless steel cleaner may be applied to maintain surface luster. Products such as Simple Green or Sheila Shine are suitable options. Always follow the product manufacturer’s application instructions.

PERIODIC DEEP CLEANING

Frequency:

Quarterly, or when visual inspection indicates excessive soil buildup.

Hot Water Extraction (Carpet Inserts):

Professional-grade hot water extraction equipment provides the most thorough cleaning for carpet inserts. This process removes embedded soil and helps restore the carpet pile. Ensure inserts are completely dry before reinstallation—typically 24 hours.

Alternative Methods:

Dry extraction compounds may be used between hot water extraction sessions. Apply the cleaning compound with a stiff brush, allow brief dwell time for soil absorption, then vacuum thoroughly.

Solution Brush Extraction:

Mechanical cleaners with counter-rotating brushes can introduce cleaning solution and extract soiled water simultaneously. This method is effective but requires careful attention to moisture extraction to prevent premature re-soiling.

SYSTEM INSPECTION PROCEDURES

Visual Assessment:

Verify that all mat panels are level and flush with the surrounding floor surface. Check for any warping, lifting edges, or uneven sections that could create trip hazards.

Hinge and Connection Points (If Applicable):

For systems with rubber or mechanical hinges, inspect each connection point to confirm secure attachment and proper function. Replace any damaged or worn components immediately.

Debris Accumulation:

Confirm that no excessive buildup exists beneath the mat modules or within drainage systems. Even small amounts of debris can cause gradual warping over time.

Insert Condition:

Examine carpet or vinyl inserts for excessive wear, staining, or damage. Plan for replacement of inserts that no longer perform effectively.

PROHIBITED CLEANING METHODS

To prevent damage to your system, NEVER use:

• Steam cleaners or steam settings on vacuum cleaners (can damage adhesives and cause warping)

• Wax or polish products (creates slip hazards)

• Abrasive cleaners or scrubbing pads (scratches aluminum)

• Chlorinated solvents or bleaching agents (degrades materials)

• High-pressure washing on installed modules (can force water beneath mats)

• Excessive force when using spatulas or scrapers (damages surfaces)

REPLACEMENT PARTS & TECHNICAL SUPPORT

Universal Floor Mats maintains an inventory of replacement inserts, hinges, and components for all our recessed grill systems. For replacement parts or technical assistance:

Phone: (301) 946-6010

Email: info@universalfloormats.com

Web: www.universalfloormats.com

When ordering replacement parts, please have your original order number or system specifications available to ensure accurate matching.

Reviews

There are no reviews yet.