Description

Recessed Coco Mats deliver unmatched sustainability and performance for high-traffic entrance applications, combining 100% natural coconut fiber construction with commercial-grade engineering to create the eco-friendly entrance solution demanded by LEED-certified buildings, environmentally conscious facilities, and organizations committed to reducing environmental impact. These premium coco fiber mats transform the byproduct of coconut harvesting, natural coir fiber from coconut husks, into highly effective entrance matting that aggressively scrapes shoes clean, absorbs exceptional moisture, and contributes to green building certification while providing the rich, natural aesthetic that elevates building entrances from utilitarian to upscale. The bristle-like texture of natural coir creates unparalleled scraping action removing dirt, debris, salt, and grit before it reaches interior flooring, while the highly absorbent natural fibers capture and hold moisture preventing wet tracking that damages floors and creates slip hazards.

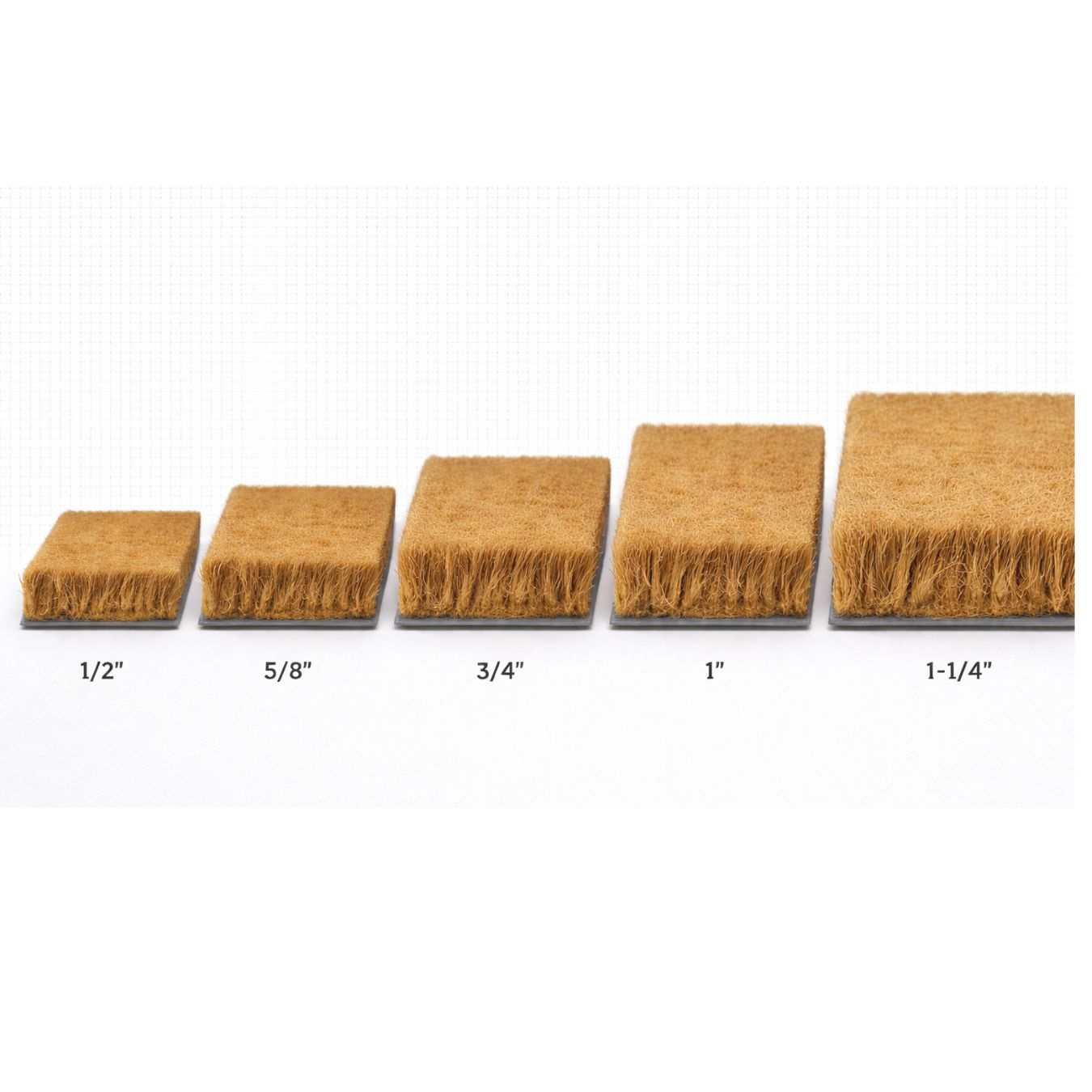

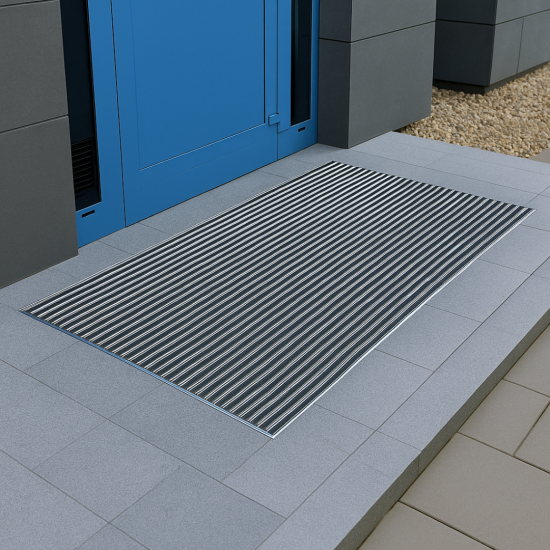

Designed specifically for recessed well installations where mats sit flush with surrounding flooring, these coco mats install without adhesives thanks to their substantial weight and vinyl backing that grips the recess floor. The deep cut-pile construction captures and holds dirt and water below the walking surface, even in extreme high-traffic environments like hotel lobbies, retail mall entrances, office building vestibules, and upscale apartment buildings, keeping entrances cleaner longer and reducing maintenance labor. Solution-dyed colored options provide fade resistance despite continuous sunlight exposure in windowed entrances, while the natural color option offers the organic aesthetic preferred in hospitality, residential, and spa applications. With five thickness options ranging from 1/2″ to 1-1/4″ and the ability to custom-cut mats to any recess dimension, these coco mats accommodate virtually any recessed entrance system.

Ideal Application

- Hospitality Applications

- Commercial Office

- Retail

- Residential

- Institutional

Maintenance Tips

Daily Maintenance

Vacuuming and Debris Removal

Recessed Cocoa Mats require daily maintenance to preserve appearance and performance:

Daily Cleaning Protocol:

- Vacuum mat thoroughly using commercial upright vacuum with beater bar

- Focus on high-traffic lanes where debris accumulates fastest

- Vacuum in multiple directions to lift particles from deep pile

- High-traffic facilities (hotels, malls): Vacuum 2-3 times daily

- Moderate-traffic facilities (office buildings): Vacuum once daily

- Light-traffic facilities (residential): Vacuum 2-3 times weekly

Initial Shedding Period:

- New coco mats will shed loose fibers for first 2-4 weeks of use

- Shedding is normal condition, not product defect

- More frequent vacuuming during break-in period reduces visible shedding

- Shedding diminishes significantly after several vacuuming sessions

- Expect temporary increase in vacuum bag filling during initial weeks

Debris Removal Best Practices:

- Remove large debris (leaves, paper) by hand before vacuuming

- Shake or beat mat if easily removable from recess (smaller sizes)

- Use stiff broom for surface sweeping between vacuum sessions

- Compressed air blowers effective for removing embedded particles (outdoor use only)

- Regular debris removal prevents particle compaction that reduces scraping effectiveness

Weekly Maintenance

Hose-Off Cleaning

For weekly deep cleaning maintaining moisture absorption:

Hose-Off Procedure:

- Remove mat from recess if practical (larger mats may clean in place)

- Hose down mat with water spray at moderate pressure

- Water temperature: Cold to lukewarm (hot water may affect vinyl backing)

- Spray from multiple angles to penetrate pile depth

- Continue hosing until water runs clear indicating dirt removal

- Flip mat and hose vinyl backing to remove debris that migrated through

- Lean vertically or hang to drain and air dry (4-12 hours depending on thickness and climate)

- Reinstall when fully dry to prevent mold/mildew in damp mats

Frequency Recommendations:

- High-traffic facilities: Weekly hose-off

- Moderate-traffic facilities: Bi-weekly hose-off

- Wet climates (frequent rain/snow): More frequent cleaning to restore absorption capacity

- Dry climates: Less frequent water cleaning acceptable

Monthly Deep Cleaning

Pressure Washing

For intensive monthly cleaning removing embedded soil:

Pressure Washer Method:

- Remove mat from recess to outdoor cleaning area

- Use pressure washer at moderate pressure (1000-1500 PSI maximum)

- Hold nozzle 12-18 inches from mat surface

- Spray systematically across entire mat front and back

- Work from one edge to other in overlapping passes

- Flip mat and pressure wash vinyl backing side

- Apply mild detergent if needed for stubborn staining (neutral pH recommended)

- Rinse thoroughly removing all detergent residue

- Lean vertically or hang to drain and dry completely (may require 24 hours)

- Reinstall only when 100% dry

Cleaning Products:

- Neutral pH all-purpose cleaners (pH 7-9) safe for natural fibers

- Mild dish soap diluted in water for general cleaning

- Avoid harsh chemicals, bleach, and strong alkaline cleaners damaging natural fibers

- Avoid fabric softeners and conditioners affecting absorbency

Seasonal Maintenance

Climate-Specific Care:

Winter (Snow/Salt Management):

- Increase vacuuming frequency to remove salt crystals and sand

- More frequent hose-off to remove salt buildup preventing fiber damage

- Salt accumulation can stiffen fibers—regular water rinsing restores flexibility

- Heavier traffic and wet conditions may require twice-weekly hosing

- Monitor for white salt deposits on mat surface indicating cleaning needed

Spring/Fall (Wet Season):

- Increased moisture means more frequent cleaning to restore absorption capacity

- Saturated mats lose effectiveness—cleaning restores capacity

- Ensure complete drying between cleanings preventing mold/mildew

- Consider rotating multiple mats allowing full drying time

Summer (High Traffic Season):

- Hotels and tourist facilities see increased traffic requiring more frequent maintenance

- Dust and dry debris accumulate faster in dry weather

- Regular vacuuming prevents particle compaction

Storage & Handling

Proper Storage (If Seasonal Use):

- Clean mat thoroughly and ensure 100% dry before storage

- Roll loosely (do not fold) to prevent permanent creases

- Store in dry, climate-controlled area if possible

- Protect from moisture preventing mold/mildew during storage

- Avoid compression by heavy objects causing fiber mat-down

- Store away from rodents attracted to natural fiber material

Handling Recommendations:

- Natural fiber mats are heavy—larger sizes require 2-3 people for safe lifting

- Wet mats significantly heavier—plan accordingly for removal and cleaning

- Drag mats carefully avoiding snagging fibers on floor edges

- Use caution when power-washing to avoid fiber damage from excessive pressure

Inspection Schedule

Weekly Quick Checks:

- Overall appearance and cleanliness

- Fiber condition and scraping effectiveness

- Edges and corners for wear or lifting

- Moisture absorption capacity (does mat feel saturated?)

- Signs of mold/mildew if mat stays damp

Monthly Detailed Inspection:

- Fiber wear patterns in high-traffic lanes

- Vinyl backing condition and adhesion to fibers

- Recess fit and flush-floor alignment

- Overall mat flatness (no buckling or warping)

- Replacement timeline projection based on wear

Cleaning Products Guide

Recommended Products:

- Neutral pH all-purpose cleaners

- Mild dish soap (Dawn, Palmolive) diluted in water

- Commercial entrance mat cleaners (manufacturer-approved)

- Stiff-bristle brooms for surface sweeping

- Commercial upright vacuums with beater bar

Products to AVOID:

- Harsh alkaline cleaners (pH above 11) damaging natural fibers

- Bleach and chlorine products causing fiber deterioration

- Oil-based cleaners leaving residue affecting absorption

- Fabric softeners reducing water absorption capacity

- Excessive pressure washing (above 2000 PSI) causing fiber damage

Expected Service Life

- High-Traffic Applications: 2-4 years (hotel lobbies, retail mall main entrances)

- Moderate-Traffic Applications: 3-6 years (office buildings, apartment buildings)

- Light-Traffic Applications: 5-8 years (residential, light commercial)

- Proper maintenance significantly extends service life

- Mat rotation equalizes wear extending total lifespan

- Natural fiber degradation is gradual—performance declines slowly

- Replacement indicated when scraping effectiveness noticeably reduced or appearance unacceptable

Technical Specifications

Material Specifications

Pile Fiber

- Material: 100% Natural Coconut Fiber (Coir)

- Source: Coconut Husk Byproduct from Food/Beverage Industry

- Construction: Cut Pile

- Pile Composition: Stiff Natural Bristle-Like Fibers

- Color: Natural (tan to brown); Solution-Dyed (colored options)

- Renewable Status: Rapidly Renewable Material (LEED Qualified)

- Biodegradability: Natural fiber biodegrades at end of service life

- Environmental Certifications: LEED MR Credit 6 eligible (rapidly renewable)

Backing Material

- Material: Commercial-Grade Vinyl (PVC)

- Purpose: Dimensional stability, fiber retention, grip

- Weight Contribution: Significant portion of total mat weight

- Installation: No adhesive required due to weight and backing grip

Water Absorption

- Capacity: Highly Absorbent

- Retention: Approximately 90% moisture return when thoroughly saturated

- Performance: One of most absorbent natural fibers available

- Moisture Management: Captured water held in fiber structure preventing release back to floors

Product Dimensions

Pile Height by Thickness:

| Thickness Option |

Pile Height (inches) |

Pile Height (decimal) |

| 1/2″ |

1/2″ |

0.50 in |

| 5/8″ |

5/8″ |

0.67 in |

| 3/4″ |

3/4″ |

0.79 in |

| 1″ |

1″ |

0.91 in |

| 1-1/4″ |

1-1/4″ |

1.25 in |

Total Mat Height:

- Equals pile height (mat thickness is pile depth)

- Select thickness matching recess depth for flush-floor installation

Total Weight by Thickness:

| Thickness |

Weight (oz/sq yard) |

Weight (lbs/sq yard) |

Weight (lbs/sq ft) |

| 1/2″ |

148 oz/sq yd |

9.25 lbs/sq yd |

1.03 lbs/sq ft |

| 5/8″ |

167 oz/sq yd |

10.44 lbs/sq yd |

1.16 lbs/sq ft |

| 3/4″ |

181 oz/sq yd |

11.31 lbs/sq yd |

1.26 lbs/sq ft |

| 1″ |

195 oz/sq yd |

12.19 lbs/sq yd |

1.35 lbs/sq ft |

| 1-1/4″ |

220 oz/sq yd |

13.75 lbs/sq yd |

1.53 lbs/sq ft |

Example Mat Weights:

- 3′ x 5′ mat at 3/4″ thickness: ~17 lbs

- 4′ x 6′ mat at 3/4″ thickness: ~30 lbs

- 6′ x 10′ mat at 1″ thickness: ~81 lbs

Color Specifications

Available Colors:

Natural (Available All Thicknesses):

- Authentic coconut fiber color

- Range: Golden tan to medium/dark brown

- Natural variation: No two mats identical (organic material)

- Color Fastness: Natural color stable; minimal UV fading

Colored Options (3/4″ Thickness Only):

- Charcoal: Deep gray-black

- Brown: Rich chocolate brown

- Gray: Neutral medium gray

- Red: Burgundy red

- Blue: Navy blue

- Green: Forest green

Color Fastness:

- To Light: Colored fibers will fade in direct relationship to light/sunlight exposure

- Solution-dyed construction provides better fade resistance than surface-dyed

- Expect gradual fading in windowed entrances with continuous sunlight

- Natural color shows less visible fading than dyed colors

- To Water: Approximately 90% color retention when thoroughly saturated

- Minimal color bleeding or transfer in normal use

Standard Sizes Available

| Width |

Length Options |

| 2′ |

3′, 4′, 5′, 6′ |

| 3′ |

3′, 4′, 5′, 6′, 8′, 10′, 12′, 16′, 20′ |

| 4′ |

4′, 5′, 6′, 8′, 10′, 12′, 16′, 20′ |

| 5′ |

5′, 6′, 8′, 10′, 12′, 16′, 20′ |

| 6′ |

6′, 8′, 10′, 12′, 16′, 20′ |

Custom Sizing:

- Available for non-standard recess dimensions

- Maximum width: 6’7″ (based on roll goods width)

- Maximum length: Limited by practical handling (contact for very large sizes)

- Custom cutting available to accommodate architectural features

Performance Specifications

Dirt and Debris Removal

- Scraping Effectiveness: Excellent (bristle-like fiber texture)

- Particle Capture: Deep pile traps dirt below walking surface

- Performance Duration: Maintains effectiveness through heavy traffic

- Best Application: Primary scraping in vestibule/entrance zone systems

Moisture Absorption

- Capacity: Highly Absorbent (one of best natural fibers)

- Retention: ~90% moisture held when saturated

- Performance: Prevents interior water tracking and slip hazards

- Climate Suitability: Excellent for wet climates, snow/rain regions

Durability & Traffic

- Traffic Classification: Heavy-Duty Commercial

- Expected Lifespan: 2-8 years depending on traffic level and maintenance

- High-Traffic Life: 2-4 years (hotel lobbies, retail malls)

- Moderate-Traffic Life: 3-6 years (office buildings)

- Light-Traffic Life: 5-8 years (residential, light commercial)

- Fiber Degradation: Gradual natural fiber breakdown over time

Flammability & Safety

- Surface Flammability: ASTM D2859 – Pass

- Equivalent Standards: CPSC FF 1-70 and DOC FF 1-70 (Pill Test)

- Smoke Density: ASTM E662 – 229 (flaming mode)

- Building Code: Complies with commercial building fire safety standards

Shedding Characteristics

- Initial Period: New mats shed loose fibers for 2-4 weeks

- Shedding Status: Normal condition, not product defect

- Duration: Minimal after several vacuuming sessions

- Maintenance Impact: Increased vacuuming frequency during break-in

Environmental Performance

- Sustainability: 100% natural, rapidly renewable material

- VOC Emissions: Minimal (natural fiber with minimal chemical processing)

- Indoor Air Quality: Low-emission material suitable for LEED buildings

- Disposal: Natural fiber component biodegradable

- Recycling: Vinyl backing recyclable through commercial recycling

LEED Certification Contribution

Indoor Environmental Quality Credit 5 (1 point):

- Credit Name: Indoor Chemical & Pollutant Source Control

- Qualification Requirements:

- Mat must be minimum 10 feet in primary direction of travel

- Semi-permanent installation (recessed cocoa mats qualify)

- Maintained on weekly basis by contracted service organization

- Deep pile construction traps dirt particles below surface preventing interior distribution

- Contribution: Recessed Cocoa Mats may contribute to LEED IEQ Credit 5

Materials & Resources Credit 6 (1 point):

- Credit Name: Rapidly Renewable Materials

- Qualification: Use materials made from plants harvested within 10-year cycle

- Cocoa Mat Compliance: 50% of mat composition is natural coir fibers from coconut palms

- Coir Status: Considered rapidly renewable material (coconuts produced year-round)

- Environmental Benefit: Reduces depletion of finite raw materials and long-cycle renewables

- Contribution: Recessed Cocoa Mats may contribute to LEED MR Credit 6

LEED Documentation Support:

- LEED specification sheet available for project documentation

- Material composition data for LEED submittal

- Maintenance guidelines for IEQ Credit 5 compliance

- Rapidly renewable material certification for MR Credit 6

Installation Specifications

Recessed Well Requirements

- Recess Depth: Must match mat thickness for flush-floor installation

- Recess Tolerance: ±1/8″ acceptable for most applications

- Floor Condition: Clean, dry, level concrete or wood substrate

- Drainage: Recess should not collect standing water

- Adhesive: Not required—mat weight and backing provide stability

Installation Procedure

- Clean recess thoroughly removing debris and dust

- Measure recess to verify mat dimensions

- Lower mat into recess ensuring even placement

- Verify flush alignment with surrounding floor

- Check all edges lie flat without curling

- No adhesive application, screws, or fasteners required

Optional Accessories

- Aluminum framing systems for professional edge finishing

- Beveled edging for surface-mount applications (not recessed)

- Transition strips for edge protection

Environmental & Operating Conditions

Recommended Use

- Primary Use: Indoor recessed entrance wells

- Climate: All climates (indoor temperature-controlled environments)

- Temperature Range: Standard building temperatures (55-85°F)

- Humidity: Normal indoor humidity levels

- Sunlight: Natural and artificial light (solution-dyed colors resist fading)

Installation Environments

- Hotel and resort main entrance vestibules

- Office building recessed entrance systems

- Retail and shopping mall tenant entrances

- Upscale residential building lobbies

- Restaurant and hospitality entrance recesses

- Institutional building main entrances

Reviews

There are no reviews yet.