| 100% solution-dyed polypropylene fibers | Provides natural coir aesthetic without organic fiber limitations; solution-dyeing creates permanent color throughout fiber that won't fade (ΔE ≤ 0.5 per ISO 105-B02), bleach, or wear off despite years of sunlight and traffic; eliminates unpredictable color variation of natural coconut fiber allowing confident multi-mat installations; polypropylene inherently resists staining (ΔE ≤ 0.3 per EN 1296) and moisture damage; synthetic composition eliminates mold/mildew risks of natural fibers; beautiful and practical walk-off entrance matting for high aesthetic applications |

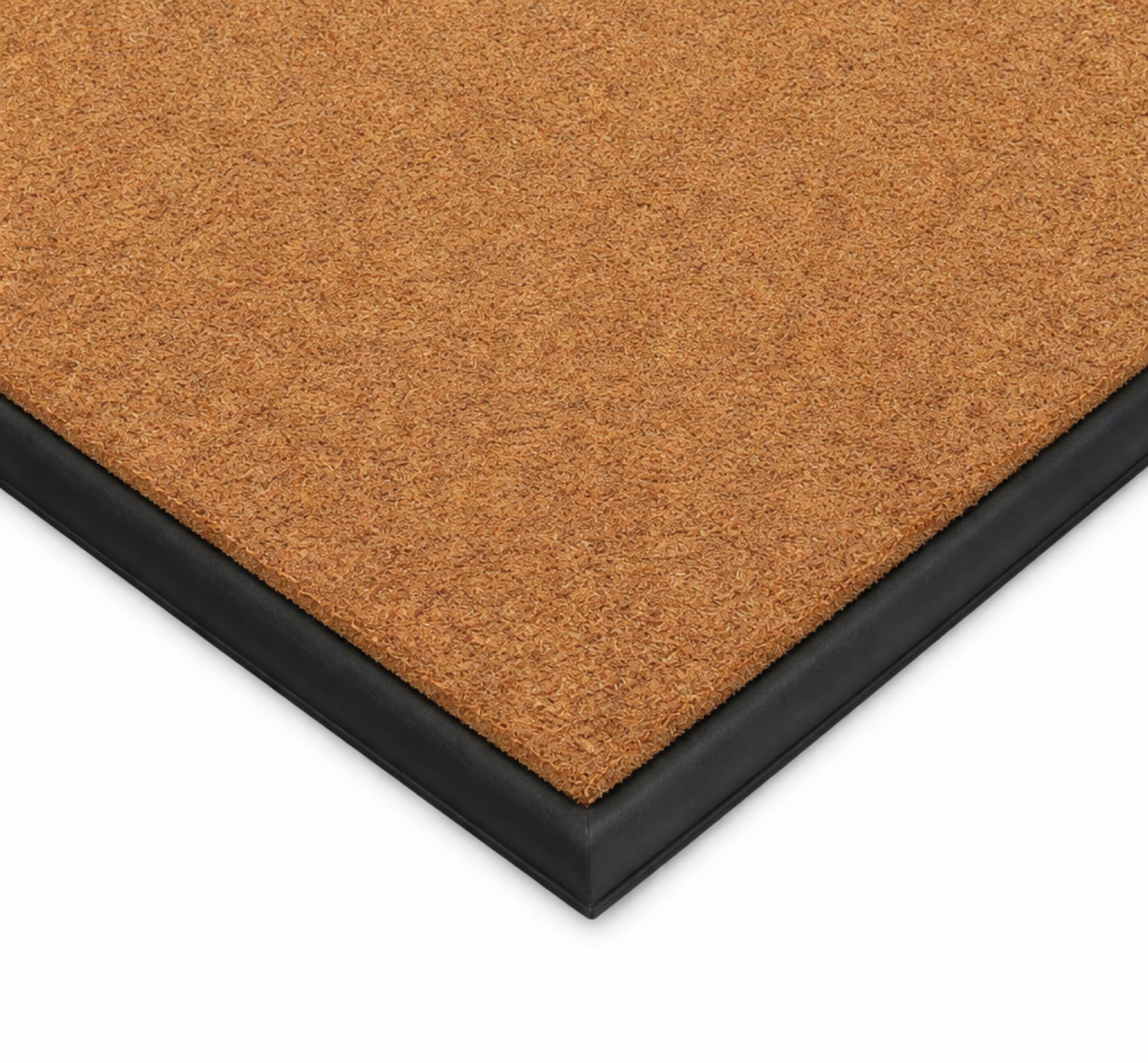

| 3.11 oz/ft² pile weight (950 g/m²) | Creates authentic bristle-like texture matching natural coir appearance; needle-punch nonwoven construction provides excellent scraping action; professional appearance suitable for upscale hospitality and corporate applications; pile density maintains appearance despite years of traffic while effectively hiding walking patterns; lighter weight than heavy commercial mats allows easier handling while maintaining durability |

| Needle-punch nonwoven construction | Creates random scattered fiber orientation replicating natural coconut coir appearance; superior durability compared to woven or tufted constructions; fibers mechanically entangled creating strong unified mat structure; effectively hides walking traffic patterns preventing visible wear lanes; fibers won't pull out or unravel; no seams or rows creating uniform appearance; manufacturing process creates authentic coir-like aesthetic ideal for high aesthetic colorful design applications |

| Natural coir aesthetic without limitations | Delivers warm organic welcoming appearance of coconut fiber entrance matting; bristle-like texture and colorful design options create upscale natural aesthetic; suitable for facilities emphasizing natural materials, sustainability image, organic themes; coordinates with wood, stone, earth-tone architectural finishes; upscale hospitality presentation; eliminates every disadvantage of natural coir while maintaining visual appeal; beautiful and practical walk-off entrance matting |

| 3/8" total thickness (10mm) | Provides substantial profile for effective scraping and dirt trapping; thickness suitable for both loose-laid surface mount and recessed well (flush-floor) installations; low enough profile to minimize trip hazards in loose-laid applications; substantial enough for professional commercial appearance; accommodates standard 3/8" recessed well systems; significant enough for effective moisture and particle capture |

| Heavy-duty high-density rubber backing (6.23 oz/ft² total) | Prevents mat movement and shifting during traffic ensuring safety and professional appearance; substantial weight keeps mat flat and stable without adhesive; grips floor surface preventing sliding; durable commercial-grade rubber withstands years of traffic without deterioration; suitable for loose-laid matting installations; eliminates need for adhesive in most applications |

| Superior UV fade resistance (ΔE ≤ 0.5 ISO 105-B02 | Solution-dyed polypropylene resists fading despite direct sunlight exposure; critical for windowed entrances and sunlit vestibules where natural coir bleaches and discolors; maintains color consistency and professional appearance through 5-8+ year service life; Delta E ≤ 0.5 demonstrates excellent light fastness; eliminates unsightly faded patches and uneven discoloration; manufacturer notes direct sunlight can damage interior finishes but Synthetic Coco Mat maintains color |

| Excellent stain resistance (ΔE ≤ 0.3 EN 1296) | Polypropylene inherently resists oil-based and water-based staining; spills clean easily without permanent discoloration; Delta E ≤ 0.3 color stability to soiling demonstrates superior stain resistance; critical for food service, retail, hospitality applications; superior to natural coir which absorbs and holds stains; maintains professional appearance in high-visibility entrances; reduces cleaning frequency and maintenance costs |

| Won't rot, mold, or mildew | Synthetic polypropylene immune to moisture-induced organic deterioration; critical for humid climates, wet seasons, and moisture-exposed interior applications; eliminates mold/mildew health concerns in healthcare and senior living facilities; suitable for interior applications near water features; no musty odor development; superior to natural coconut fiber vulnerable to moisture damage; improves interior air quality |

| Five colorful design options | Designer-curated palette from black through silver greys coordinates with any architectural finish; enables soil-hiding optimization (black for maximum) or aesthetic preference (light grey for contemporary); solution-dyed colors perfectly consistent from mat to mat allowing confident multi-location rollouts; expanded palette beyond natural coir's tan/brown limitation; professional neutral options suit corporate, hospitality, healthcare applications; high aesthetic colorful design for beautiful practical walk-off entrance matting |

| Custom-cut to any dimension | Accommodates unique vestibule shapes, recessed wells, architectural features; eliminates gaps and improper fit; creates professional tailored appearance; fits odd-sized interior entrances and non-standard recesses; maximizes coverage and performance; available up to 6'6" width and 65.6' continuous length; custom cutting available for perfect installation fit |

| Anti-static properties (< 2kV ISO 6356) | Prevents uncomfortable static discharge shocking building occupants; reduces static-induced dust attraction keeping mats cleaner; protects sensitive electronics in facilities with computer equipment; comfortable user experience in dry winter months; suitable for healthcare with electronic medical equipment; ISO 6356 tested and verified static dissipation performance |

| Superior dimensional stability (ISO 2551) | ≤1.2% maximum shrinkage and ≤0.5% maximum expansion ensures consistent size; critical for recessed well installations requiring precise fit; won't buckle from expansion or create gaps from shrinkage; maintains flush-floor alignment and professional appearance; superior to natural coir with significant moisture-induced size changes; ISO 2551 tested dimensional performance provides confidence in long-term fit |

| 3-year limited manufacturer warranty | Demonstrates manufacturer confidence in long-term performance and durability; provides protection and recourse for manufacturing defects; superior to natural coir typically sold without warranty; peace of mind for commercial installations; documents expected service life for facilities planning; warranty support through Universal Floor Mats |

| Interior-only application design | Optimized for climate-controlled interior applications without outdoor weather exposure; must be used for interior applications only per manufacturer specifications; suitable for building lobbies, vestibules, interior entrances; not recommended for uncovered outdoor exposure; proper application in intended environment ensures maximum performance and lifespan; improves air quality and reduces maintenance costs in interior spaces |

| Loose-laid matting installation | No adhesive required—rubber backing and weight provide stability; easy removal for cleaning underneath mat and floor; relocatable as facility needs change; simple installation without special tools; heavy-duty rubber backing prevents shifting; can be used in both surface mount and recessed well applications; practical walk-off entrance matting solution |

| Hides walking traffic patterns | Needle-punch nonwoven construction and scattered fiber orientation prevent visible wear lanes; maintains uniform appearance despite concentrated traffic; superior to loop-pile or cut-pile constructions showing traffic patterns; professional appearance throughout service life; reduces need for frequent replacement due to appearance rather than function |

| Color stability to water (ΔE ≤ 0.4 ISO 105-E01) | Water exposure won't affect color or cause bleeding; critical for wet climates and snow-melt exposure; maintains color integrity despite moisture; superior to natural coir which can discolor when wet; tested per ISO 105-E01 standard for water fastness |

| Color stability to rubbing (ΔE ≤ 0.4 wet/dry) | Color won't rub off or transfer despite friction from foot traffic; tested both wet and dry conditions; maintains color integrity under heavy use; superior to surface-dyed products where color wears off; Delta E ≤ 0.4 demonstrates essentially imperceptible color change |

Reviews

There are no reviews yet.