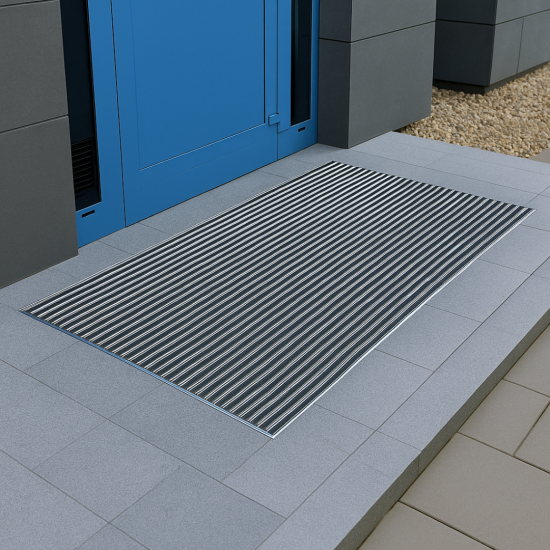

| 18" x 18" x 1/4" modular tile format | Provides unlimited design flexibility creating custom-sized entrance systems for any space; accommodates irregular shapes, complex architectural features, columns, and curved walls impossible to fit with standard roll goods; enables wall-to-wall coverage eliminating gaps where dirt accumulates; allows phased installation and expansion as budget permits; simplifies transportation and handling versus heavy rolls; enables individual tile replacement for damaged sections dramatically reducing lifetime costs |

| WaterHog bi-level surface construction | Delivers proven dirt-trapping and moisture-absorption performance through raised rubber-reinforced nubs that scrape shoes clean while recessed channels capture and hold particles below shoe level; prevents re-tracking of debris onto interior floors; reduces interior cleaning labor and floor finish maintenance; protects flooring investment from abrasive particle damage; maintains clean professional appearance despite heavy traffic |

| Rubber-reinforced face nubs | Prevents pile crushing that destroys lesser carpet tiles in high-traffic lanes; maintains scraping effectiveness through years of continuous use; extends service life from typical 3-5 years to 7-10+ years in commercial applications; reduces replacement frequency and lifetime costs; ensures consistent performance in extreme traffic applications like hotel lobbies and retail mall entrances |

| Solution-dyed PET surface (30 oz/sq yard) | Provides exceptional fade resistance despite years of sunlight exposure in windowed entrances; resists staining from spills, salt, and environmental contaminants; color penetrates entire fiber rather than surface coating ensuring appearance retention as fibers wear; quick-drying properties restore functionality between traffic surges; won't rot or deteriorate from moisture exposure; suitable for wet climate installations and outdoor applications |

| 90%+ recycled plastic bottle content | Demonstrates environmental responsibility by diverting plastic bottles from landfills (each case diverts 150+ bottles); supports LEED Materials & Resources credits for green building certification; reduces virgin petroleum consumption in fiber manufacturing; communicates organizational sustainability commitment to customers and tenants; qualifies for environmentally-preferable purchasing programs; authentic sustainability story for marketing and corporate responsibility reporting |

| SBR rubber cleated backing (100-mil) | Grips floor securely when installed with proper adhesive preventing tile shifting and buckling; 20% recycled car tire rubber content adds environmental credentials; universal cleat pattern accommodates both surface mount and recessed well applications; provides structural stability and dimensional integrity; maintains flat profile preventing edge curling and trip hazards; durable backing withstands heavy traffic without delamination |

| Individual tile replacement capability | Transforms entrance matting from disposable product to serviceable floor system; replace worn tiles in high-traffic lanes without discarding entire installation; dramatically reduces lifetime costs compared to traditional mats requiring complete replacement; minimizes waste and environmental impact; extends effective service life to decades with strategic tile replacement; maintains pristine appearance indefinitely through targeted replacement |

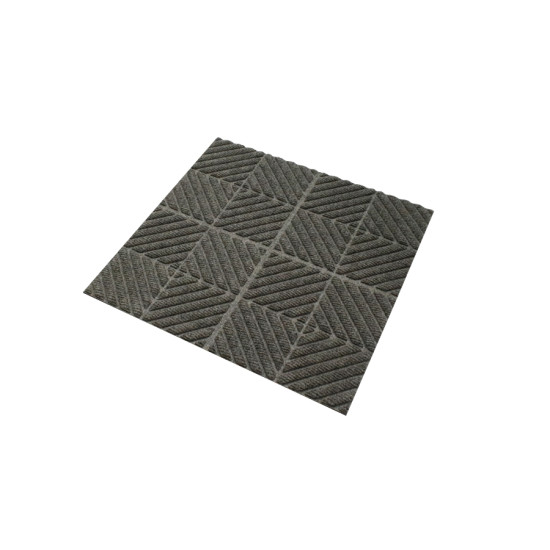

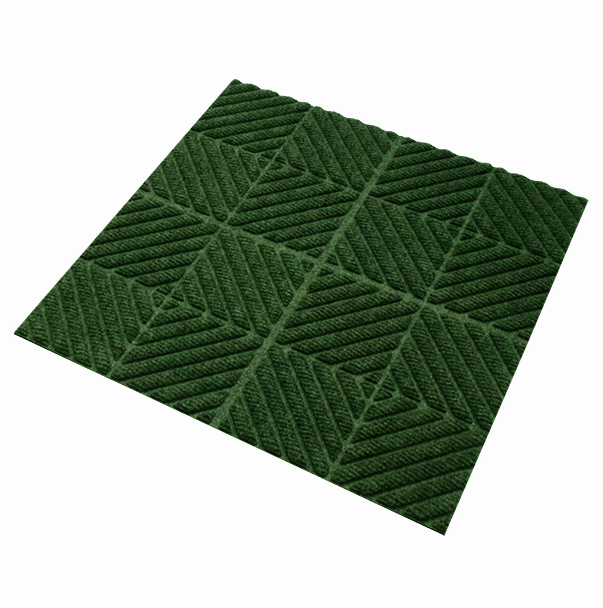

| Three pattern options (Diamond, Diagonal, Geometric) | Provides design versatility coordinating with architectural aesthetics; enables visual differentiation between facility locations or functional zones; creates visual interest without overwhelming building design; all patterns deliver identical performance—choice is purely aesthetic; allows brand expression and design customization; coordinates with contemporary, traditional, or transitional architecture |

| Seven solution-dyed color options | Enables color coordination with corporate branding, school colors, architectural finishes, and facility design themes; charcoal color hides soil in extreme traffic; neutral browns and grays coordinate with any palette; bold colors (Bordeaux, Evergreen, Navy) create branded statements; solution-dyeing ensures permanent color won't fade or wear off; accommodates diverse design requirements from conservative corporate to vibrant retail |

| NFSI-certified high-traction surface | Provides third-party verified slip resistance meeting National Floor Safety Institute rigorous standards; reduces facility slip-and-fall liability and insurance concerns; demonstrates safety compliance for risk management and legal defense; maintains traction in wet conditions critical for entrance applications; safer than hard flooring or low-pile carpet alternatives; contributes to comprehensive facility safety programs |

| FeatureBenefit18" x 18" x 1/4" modular tile formatProvides unlimited design flexibility creating custom-sized entrance systems for any space; accommodates irregular shapes, complex architectural features, columns, and curved walls impossible to fit with standard roll goods; enables wall-to-wall coverage eliminating gaps where dirt accumulates; allows phased installation and expansion as budget permits; simplifies transportation and handling versus heavy rolls; enables individual tile replacement for damaged sections dramatically reducing lifetime costsWaterHog bi-level surface constructionDelivers proven dirt-trapping and moisture-absorption performance through raised rubber-reinforced nubs that scrape shoes clean while recessed channels capture and hold particles below shoe level; prevents re-tracking of debris onto interior floors; reduces interior cleaning labor and floor finish maintenance; protects flooring investment from abrasive particle damage; maintains clean professional appearance despite heavy trafficRubber-reinforced face nubsPrevents pile crushing that destroys lesser carpet tiles in high-traffic lanes; maintains scraping effectiveness through years of continuous use; extends service life from typical 3-5 years to 7-10+ years in commercial applications; reduces replacement frequency and lifetime costs; ensures consistent performance in extreme traffic applications like hotel lobbies and retail mall entrancesSolution-dyed PET surface (30 oz/sq yard)Provides exceptional fade resistance despite years of sunlight exposure in windowed entrances; resists staining from spills, salt, and environmental contaminants; color penetrates entire fiber rather than surface coating ensuring appearance retention as fibers wear; quick-drying properties restore functionality between traffic surges; won't rot or deteriorate from moisture exposure; suitable for wet climate installations and outdoor applications90%+ recycled plastic bottle contentDemonstrates environmental responsibility by diverting plastic bottles from landfills (each case diverts 150+ bottles); supports LEED Materials & Resources credits for green building certification; reduces virgin petroleum consumption in fiber manufacturing; communicates organizational sustainability commitment to customers and tenants; qualifies for environmentally-preferable purchasing programs; authentic sustainability story for marketing and corporate responsibility reportingSBR rubber cleated backing (100-mil)Grips floor securely when installed with proper adhesive preventing tile shifting and buckling; 20% recycled car tire rubber content adds environmental credentials; universal cleat pattern accommodates both surface mount and recessed well applications; provides structural stability and dimensional integrity; maintains flat profile preventing edge curling and trip hazards; durable backing withstands heavy traffic without delaminationIndividual tile replacement capabilityTransforms entrance matting from disposable product to serviceable floor system; replace worn tiles in high-traffic lanes without discarding entire installation; dramatically reduces lifetime costs compared to traditional mats requiring complete replacement; minimizes waste and environmental impact; extends effective service life to decades with strategic tile replacement; maintains pristine appearance indefinitely through targeted replacementThree pattern options (Diamond, Diagonal, Geometric)Provides design versatility coordinating with architectural aesthetics; enables visual differentiation between facility locations or functional zones; creates visual interest without overwhelming building design; all patterns deliver identical performance—choice is purely aesthetic; allows brand expression and design customization; coordinates with contemporary, traditional, or transitional architectureSeven solution-dyed color optionsEnables color coordination with corporate branding, school colors, architectural finishes, and facility design themes; charcoal color hides soil in extreme traffic; neutral browns and grays coordinate with any palette; bold colors (Bordeaux, Evergreen, Navy) create branded statements; solution-dyeing ensures permanent color won't fade or wear off; accommodates diverse design requirements from conservative corporate to vibrant retailNFSI-certified high-traction surfaceProvides third-party verified slip resistance meeting National Floor Safety Institute rigorous standards; reduces facility slip-and-fall liability and insurance concerns; demonstrates safety compliance for risk management and legal defense; maintains traction in wet conditions critical for entrance applications; safer than hard flooring or low-pile carpet alternatives; contributes to comprehensive facility safety programsIndoor/outdoor rated performance | Suitable for covered outdoor entrances, vestibules, and transition zones; withstands temperature extremes, UV exposure, rain, snow, and ice melt without deterioration; salt and ice melt won't damage fibers or backing; year-round performance in harsh climates; versatile application expands usage beyond traditional indoor-only entrance mats; eliminates need for seasonal mat changes |

| Quick-drying PET fiber system | Restores full functionality between traffic surges critical for busy entrances; wet-climate suitability where mats face continuous moisture exposure; prevents mold and mildew growth in damp conditions; reduces slip hazards from saturated mats; suitable for entrances near pools, spas, or water features; faster return to service after cleaning versus slow-drying natural fibers |

| Anti-static properties | Prevents uncomfortable static discharge shocking building occupants; protects sensitive electronics in facilities with computer equipment and servers; suitable for healthcare environments with electronic medical equipment; eliminates static-induced dust attraction that makes carpets appear dirty; comfortable user experience in low-humidity climates prone to static; meets requirements for static-sensitive environments |

| FF-2-70 flammability compliance | Passes federal flammability standard for commercial carpets ensuring building code compliance; suitable for all occupancy types and commercial applications; reduces facility fire safety liability; meets inspection and insurance requirements; demonstrates responsible material selection for life safety; suitable for high-occupancy buildings and public spaces |

| Solvent-free adhesive installation | Eliminates harmful solvent exposure protecting installer health and building occupants; low-VOC installation supports indoor air quality and LEED IEQ credits; odor-free installation allows occupied building installation without disruption; environmentally responsible installation practice; complies with green building specifications and sustainable procurement programs |

| Each case covers 27 sq ft (12 tiles) | Simplifies ordering and estimating—measure square footage and divide by 27 for cases needed; efficient packaging reduces shipping costs and environmental impact; manageable case size for handling and storage; allows incremental purchasing for phased installations; standardized packaging streamlines inventory management for facilities with multiple locations |

Reviews

There are no reviews yet.