| Interlocking edge system (no adhesive) | Eliminates adhesive cost, professional installer fees, floor damage, application time, and cure waiting; enables DIY installation by facility staff saving thousands in labor costs; allows easy relocation or expansion; removes tiles without floor damage perfect for rental spaces; immediate traffic after installation with no cure time; tiles disconnect for deep cleaning underneath; cost-effective solution for budget-conscious facilities |

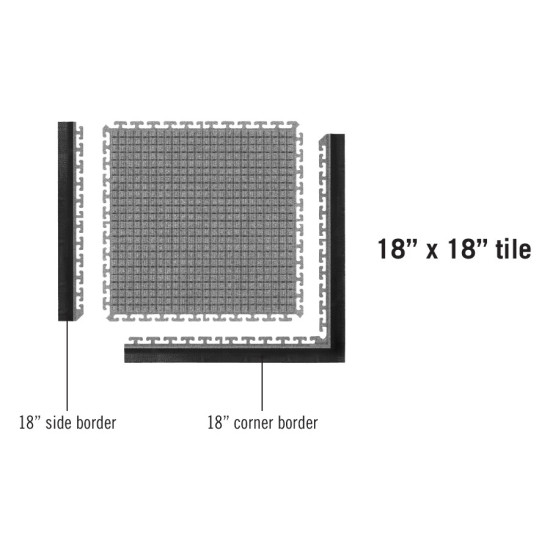

| 18" x 18" or 36" x 36" tile sizes | Provides application flexibility—18" tiles for detailed areas and recessed wells, 36" tiles for faster coverage of large spaces; accommodates different installation scenarios; allows mixing sizes if needed; enables precise fitting through smaller increments (18") or rapid coverage (36"); tile size selection optimizes installation efficiency and material usage |

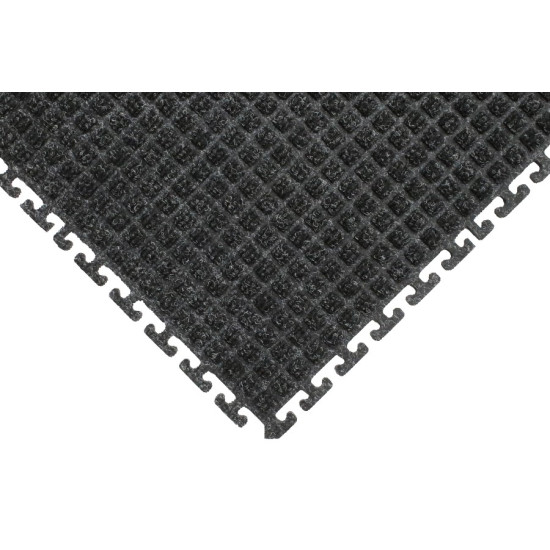

| WaterHog bi-level surface construction | Delivers proven dirt-trapping and moisture-absorption performance through raised rubber-reinforced nubs scraping shoes clean while recessed channels capture particles below shoe level; prevents re-tracking of debris onto interior floors; reduces interior cleaning labor and floor finish maintenance; protects flooring investment from abrasive particle damage; maintains clean professional appearance despite heavy traffic; industry-standard technology trusted worldwide |

| Rubber-reinforced face nubs | Prevents pile crushing that destroys lesser carpet tiles in high-traffic lanes; maintains scraping effectiveness through years of continuous use; extends service life from typical 3-5 years to 7-10+ years in commercial applications; classic square "waffle" pattern industry standard for recessed matting; ensures consistent performance in extreme traffic applications; reduces replacement frequency and lifetime costs |

| 24 oz/sq yard solution-dyed polypropylene | Provides standard WaterHog fabric weight balancing durability and cost; solution-dyeing creates permanent color throughout fiber that won't fade, bleach, or wear off despite years of sunlight and traffic; polypropylene inherently resists staining and moisture damage; quick-drying properties restore functionality between traffic surges; won't rot or deteriorate from moisture exposure; suitable for indoor and outdoor applications; anti-static properties prevent discharge and dust attraction |

| 90%+ recycled plastic bottle content | Demonstrates environmental responsibility by diverting plastic bottles from landfills; supports LEED Materials & Resources credits for green building certification; reduces virgin petroleum consumption in fiber manufacturing; communicates organizational sustainability commitment to customers and tenants; qualifies for environmentally-preferable purchasing programs; authentic sustainability story for marketing and corporate responsibility reporting; eco-friendly polyester from recycled drink bottles |

| 200-mil SBR rubber backing with interlocking edges | Provides substantial backing thickness for stability and durability; precision-molded interlocking edges create seamless tile-to-tile connections; universal cleated pattern prevents shifting without adhesive; contains recycled rubber content adding environmental credentials; heavy backing weight keeps tiles flat and stable; durable commercial-grade rubber withstands years of traffic; interlocking design unique advantage over adhesive-required tiles |

| Individual tile replacement capability | Transforms entrance matting from disposable product to serviceable floor system; replace worn tiles in high-traffic lanes without discarding entire installation; dramatically reduces lifetime costs compared to traditional mats requiring complete replacement; minimizes waste and environmental impact; extends effective service life to decades with strategic tile replacement; maintains pristine appearance indefinitely through targeted replacement; simply disconnect damaged tile, connect replacement tile |

| Classic square "waffle" pattern | Industry-standard surface design for recessed matting trusted in Class A buildings, hospitals, schools, lobbies nationwide; proven multi-directional scraping from all approach angles; professional appearance suitable for upscale facilities; familiar aesthetic building occupants associate with quality; coordinates with architectural finishes without overwhelming design; time-tested pattern with decades of performance history |

| Four solution-dyed color options | Enables color coordination with corporate branding, architectural finishes, and facility design themes; medium grey most popular versatile neutral; dark brown and charcoal for soil hiding; evergreen for school colors and recreation facilities; solution-dyeing ensures permanent color won't fade or wear off; accommodates diverse design requirements; professional neutral options suit commercial, healthcare, educational applications |

| NFSI-certified high-traction surface | Provides third-party verified slip resistance meeting National Floor Safety Institute rigorous standards; reduces facility slip-and-fall liability and insurance concerns; demonstrates safety compliance for risk management and legal defense; maintains traction in wet conditions critical for entrance applications; safer than hard flooring alternatives; contributes to comprehensive facility safety programs; certified high-traction performance |

| Indoor/outdoor rated performance | Suitable for covered outdoor entrances, vestibules, and climate-controlled spaces; withstands temperature extremes, UV exposure, rain, snow, and ice melt without deterioration; salt and ice melt won't damage fibers or backing; year-round performance in harsh climates; versatile application expands usage beyond traditional indoor-only entrance mats; eliminates need for seasonal mat changes |

| DOC-FF1-70 fire resistance | Passes federal standard for carpet surface flammability ensuring building code compliance; suitable for all occupancy types and commercial applications; reduces facility fire safety liability; meets inspection and insurance requirements; demonstrates responsible material selection for life safety; suitable for high-occupancy buildings and public spaces |

| Directional arrows on tile backing | Ensures consistent pile direction across entire installation creating uniform appearance; printed arrows on each tile backing indicate fabric pile direction; aligning arrows during installation creates seamless visual consistency; prevents mismatched appearance from reversed tiles; simple quality control for installers; professional finished look |

| Corner and side borders available | Provides professional finished edge with beveled transitions reducing trip hazards; corner borders create safe 90-degree transitions at perimeter corners; side borders provide beveled edge along perimeter length; optional for recessed installations, recommended for surface-mount; can be glued for heavy border traffic; complete professional installation appearance |

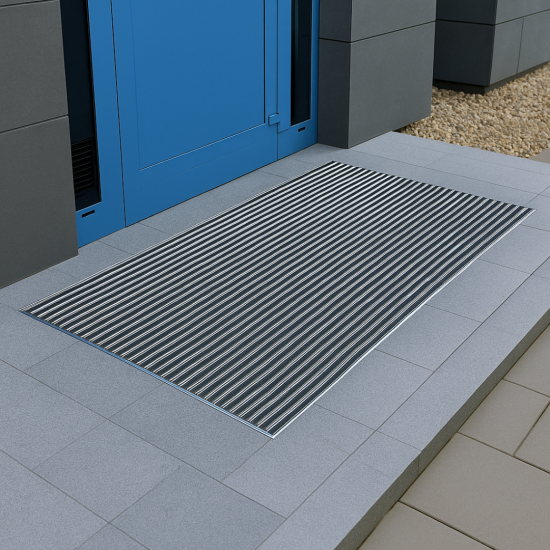

| Wall-to-wall installation capable | Enables coverage from wall to wall eliminating gaps where dirt accumulates; professional built-in appearance superior to floating mats; install from center outward cutting edge tiles to fit walls; create defined entrance zones with architectural impact; maximizes WaterHog performance across entire entrance area |

| Made in USA quality | Ensures consistent quality control and manufacturing standards; supports American manufacturing and jobs; shorter supply chain reducing freight environmental impact; quality assurance from M+A Matting 50+ years mat manufacturing experience; reliable product availability and replacement tile consistency |

Reviews

There are no reviews yet.